Not ‘may well be old’, but we is old!

Ok, so I think what threw me was your formula in the first post…

I got tangled up in it rather than reading and understanding that you clearly stated…

Once I stopped fretting over the formula it all came together pretty smoothly.

There are two places to enter scaling.

- PAC Control.

- groov Mange.

Of course, since there are two places, there is a wrinkle…

PAC Control will over write the scaling in groov Mange, but we do give a check box option to use the groov Manage offset and gain rather than the PAC Control one.

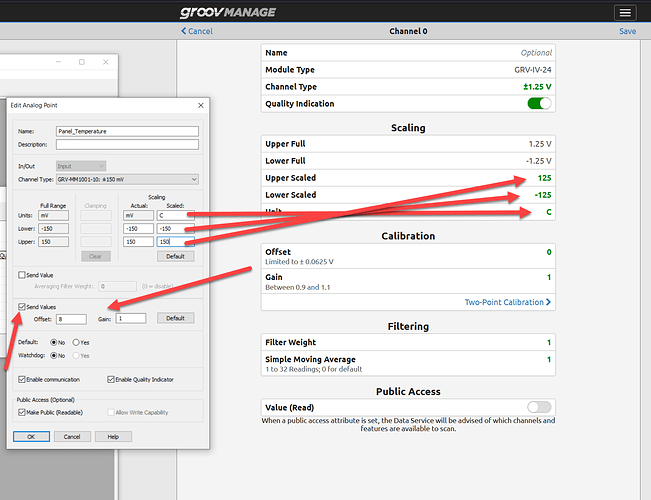

Lets take a screenshot…

Its not perfect since one is a RIO and the other is an EPIC, but its close enough in regards to talking about the scaling, offset and gain.

Since your temperature sensor is linear, we can do a two point line.

0mv is 0C and 1200mV is 120C. And you are looking for a range of 0 to 115C

So we just have to set the analog input card scaling to match. The GRV-ITMI-8 is bipolar. We are going to use the range of ±1200.0mV (Since we can’t clamp the lower at 0v, we need the scaling ‘curve’ to go through zero).

So we really should set the lower to be -1200mV to be -120C and the upper 1200mV to be 120C

In this way, if the temp does goes -0.1 or over 115C, its not a problem.

I have done this in groov Manage and PAC Control in the screenshot.

The important thing to note is that PAC Control will, on download and strategy run, overwrite groov Manage scaling with its.

You don’t have an option here, it will blow away any scaling you set up in groov Manage. (And the name and the channel type).

Now if you need to tweak things a tiny bit to get the temperature dead nuts on, you can use the gain and offset.

In this case, see there is a check box in the PAC Control, if you don’t check it, you can use the offset and gain in groov Manage, if you do check it, what you put in PAC Control will over write whats in groov Manage. So in the case of the screen shot, once I download and run, 8 and 1 would be sent and over write the 0 and 1.

If your pressure gauge is linear, same setup with the GRV-IVI-12.

@grant1 You got it, I guess I did not think the song was as big over here as in Australia, the link you included put me straight, it was a big hit everywhere.

@david.timms KB’s are for bugs, not ‘how to’ stuff. But, I am going to talk to the doc people since they do point to doing the offset and gain in PAC Manager which is not an option with EPIC and it needs to be clearer in the PAC Control users guide and in the PAC Manager users guide.