This is the first groovEPIC I am using and would like advice as to should I use PAC Display Runtime or groovView for HMI for the customer. I plan to use PAC Control for programming the EPIC. At first the system will be a standalone with a crossover cable from laptop to EPIC. When we get network approval at the facility then I will have a need for groovView. Thanks, Larry

Hi Larry! So there’s no “right” or “wrong” answer here.

PAC Display is a Windows based HMI software that’s been around quite some time. I think you have some experience already in that arena, so you know what it does pretty well. With PAC Display, you have faster scan rates and more historical logging capabilities, but you’re limited to the single Windows PC running the software.

groov View on the other hand is fully web-based. With groov View, it’s a once per second scan time and a web UI. Therefore, you will be able to view the HMI screens inside of any web browser (or the groov View mobile app) - as long as it has an Ethernet path back to the controller where it’s running.

For what it’s worth, if I were developing something today, I’d go with groov View, as I feel the web-based aspect is (and will continue) to be extremely important to customers’ expectations in the future.

Thanks Dan! I agree, I thought about it some more and considering I will probably be adding a external monitor to the laptop for others to view. I noticed with groovView it will resize the windows to fit the monitor. So, as I develop the HMI on the laptop in groovBuild the external monitor will have a full screen. However, the scientists will still need data collection. Could I use the PAC Display Runtime just for configuring historical data files? What is your suggestion? Thanks again, Larry

You can run PAC Display just for data logging.

But, that said, I’d love to hear more about the scientists data collection needs… What sort of size of files, what frequency of logging (once a second or once a minute for example), what format, CSV or something else, how many data points, 10 or 100, ie roughly how many points how often… Lastly, do they expect to download it via thumb drive or get it via email (email on the NASA network might be ‘fun’ to setup).

I guess what I am getting at is that EPIC has options for this sort of thing and we need to take a better look at the nail to know what sort of hammer to use.

Typically the data interval is 5 minutes, for troubleshooting I create 10 second or 1 minute graphs. Number of data points, 10 to 12 for this system. CVS tab format is preferred. It won’t be on a network until approval is complete, in the meantime thumb drive to either the laptop or EPIC.

Sounds like the PAC Display Data Historian will be perfect then.

There is a section in the users guide on it, but feel free to drop in here if you have any questions. Its been a while since I have used that function, but can refresh my memory or there are others that use it daily lurking here no doubt.

Thanks Ben, I use PAC Display Runtime for all our data collection currently. I notice by default the CVS is set to comma delimited, I always change it to tab because in tab format it opens neatly and easily in Excel. Comma delimited causes me to have to tell Excel how to display it. In the future I plan to use OptoDataLink to send data to a database server, then write Node Red programming for end user to retrieve data from an office computer.

Side question, if I have a groovEPIC on the network can I use it like I use the groovEdge AR1? Meaning, will the built in groovView in the EPIC behave just like the AR1? Will I be able to add tags from other PAC R1 controllers on the network for example?

Thanks, Larry

Yes, no problem. As long as the R1 controller is on the same network segment as the EPIC just go into groov View build mode, add an Opto 22 controller, put the IP address and the idb.txt file and build your screens.

Network segment, meaning IP addresses that are aaa.bbb.ccc.ddd and aaa.bbb.ccc.eee can talk to each other, but aaa.bbb.ccc.ddd and aaa.bbb.ddd.eee cannot?

Use the groov Manage network tools and make sure you can ping the R1 controller from the groov EPIC.

If so, you should be good-to-go.

Okay, thanks! I appreciate your support, Larry

New question about setting up groovEPIC. In the past for light detection I used a photocell that varied resistance from 2K to 8K depending on the light level. I connected them to PAC SNAP AIV-8 and installed a 1K resister from ground to photocell using a 5VDC PS. I replicated the same set up with the IV-24 in our EPIC system, it doesn’t work. I noticed that the AIV-8 impendence is 1M ohm and the IV-24 is 9.6M ohm. Would that be the cause of it not working? I have tried using 1K, 10K, 10M resisters for the voltage divider but still no change in signal input. Thanks, Larry

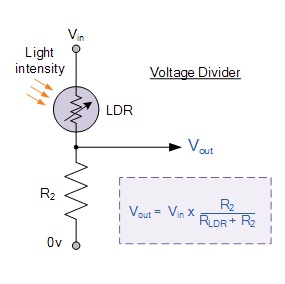

This is the wiring I am following.

Vin is +5VDC, Vout goes to the IV-24 input, 0VDC negative side of power supply. With the PAC SNAP AIV-8 I would normally get about 0.002 VDC when the lights were off, lights on 4.85 VDC at Vout when using a 1K 1/4W resister for R2.

Ok, got it working.

Due to the high input impedance, you really do need to drive it a bit harder.

In my case, R2 (from your diagram) needs to be around 250 ohms.

With that it goes from around .8v with a cupped hand to 4.8v with my cell phone flashlight.

Anything from about 800 ohm or higher just does nothing.

Do you have a resistor decade box? Makes it super quick to find the correct value for your desired output.

I wanted to speed things up, so I also set the simple moving average on the input to 1 (ie disabled it), but the default of 4 works, its just… well… filtered.

Thanks for the fun little project, hope that helps you get up and running.

Alright Ben! Way to go! I just didn’t think of going lower with the ohms for R2 would work. Sometimes trial and error will get you there eventually. I will try it out tomorrow, have a great weekend!