Hello,

Can I use the sensor below with groov system i/o? I do not understand the term constant current source. Please someone advise.

Thanks

Hello,

Can I use the sensor below with groov system i/o? I do not understand the term constant current source. Please someone advise.

Thanks

Any reason you cant use the 3 wire hook up and skip the constant current source?

Thank you, Ben.

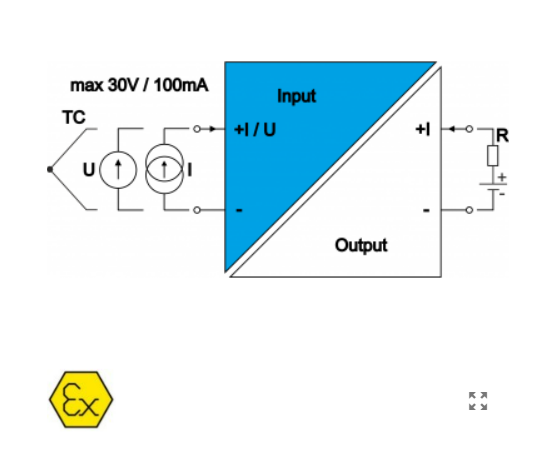

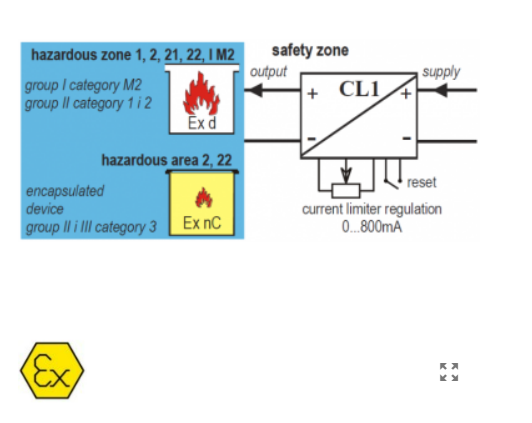

Just wanted to make sure and to skip the transmitter. TBH, I never tried 2 wire IEPE sensor before. I use to worked with 3 or 4 wire sensor (a bit old version). The sensor output is 100 mV/g and the maximum is 70g so, I can use RIO for this application then.(I guess) In the market the 2-wire is much cheaper than 3-wire for ATEX application. There is anther manufacturer spec. Please see below.

I’m not sure that can we modify the 2 wire to compatible with groov I/O?

Thanks gain, Suchet

Ok. Not sure I follow your logic on why not use three wire, but it seems to be locked in to two wire.

Your first post says ‘groov system’, but your second post says ‘groov RIO’.

Quite a difference between the EPIC and the RIO as you know.

I was going to suggest assuming 2 wire (constant current required) and RIO, you will need to use one channel on the RIO as a analog output and this is your current source and set it to be say 5ma output, that’s your constant current source.

Then wire another RIO input as analog input voltage and be sure to keep in mind that RIO has a common neutral (in this case, it will be fine as per your first post circuit diagram).

However, while a nice trick and has got a few customers going, it will not work for you. The RIO mA output is a max of 10vDC.

The spec sheet requires that the constant current source be around 18 to 28v… that’s more than the RIO set to mA output can deliver.

So you will need to skip the analog output idea and just pay the few extra bucks and get a constant current source at say 24VDC at ~5mA and use a resistor voltage divider (your first spec sheet is missing the sensor analog output voltage) to drop it down to the RIOs zero to ten volts DC input.

Test it with a meter before hooking it up!

Bottom line, yes, you can get this sensor to within the RIO analog input DC range of 0 to 10vDC.

Use an external constant current source and two resistors and then re-scale the RIO analog input in groov Manage to get your reading.

Awesome, Thank you so much. It’s a great advice sir! ![]()

Isn’t the signal out put an alternating wave form (AC) on these? Note the capacitor in the circuit diagram which removes the DC signal. I think you will need something to process the signal.

I only have experience with motor vibration sensors and the ones I integrated were modbus.

Thank you, Philip.

This project is quite challenge. I must measure the vibration for low speed machinery. From my research, looks like I will need a very low frequency response somewhere at around @ 1Hz minimum and seems very difficult to find for (IECex). Yes, I can get that type of sensor as well with modbus RTU unfortunately, the frequency response start at 10 Hz. We thinking about 3 - axis vibe sensor and maybe 2 output vibration plus temp in one sensor. The biggest barrier is the signal conditioner / signal transmitter for this type the price is more expensive than RIO itself. There is other option with 4-20 mA output but it cannot get the 1 Hz frequency response. If you have source for this spec then please advise.

Thank you so much for your comment.

Sorry, I don’t have any suggestions, I only have superficial knowledge on these.

Thank you anyway, Philip.

After follow up with @Beno advice, looks like I probably can save 400 USD per sensor. Please see below.

Thanks again…

Great question.

I did not read the symbol as a cap, but I can see how it could be.

With zero part numbers and cut off spec sheet screenshots its hard to say what the output is.

If it is a frequency I have used SNAP I/O in the past to read audio frequencies for a customer that wanted to measure background factory noise and any peak sounds.

Of course we don’t currently have similar modules or inputs for EPIC or RIO at this stage.

@Suchet.b I’d go carefully into this one and look at more options once you have more facts in hand.

Feel free to keep this thread going if you have any more questions.

BTW I’m currently testing two of these units on our air compressors here at Opto:

Using Node-RED to gather the data from the receiver.

Here is a msg.payload from just now:

Then putting some of the key values into groov View data store.

Pretty clear where the compressor turned on this morning.

One thing that I am not sure about is that with only slow update rates, I guess you just have to track and alert on out of band values. Seems odd.

To be clear, we are not endorsing these sensors or suggesting that they are suitable for your applicaiton, just mentioning that there are somewhat EPIC/RIO plug and play vibration sensors out there.

Thank you @Beno for the option. Looks like I have many options now if not require special measurement in hazardous area. I have possibility to use senser that come with 4-20 mA output and HART protocol or IEPE sensor with manufacturer signal conditioner / gateway to avoid pain in the field then ![]()

For general purpose, it’s fine for me because I have plenty of choices it’s depending on the budget/spec.

Looking forward to see IEPE input i/o from you guys.

Thanks again.