Using one of our RIO demo centers which has an ICTD temperature sensor with a resistor in the probe, I was able to run some PID tests to see if I could see what you are describing.

Starting first with straight analog in analog out control of the PID loop:

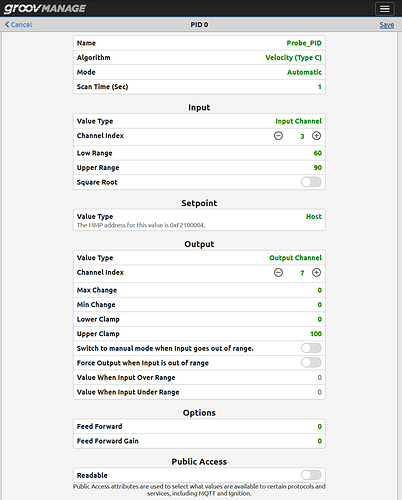

This is how its configured.

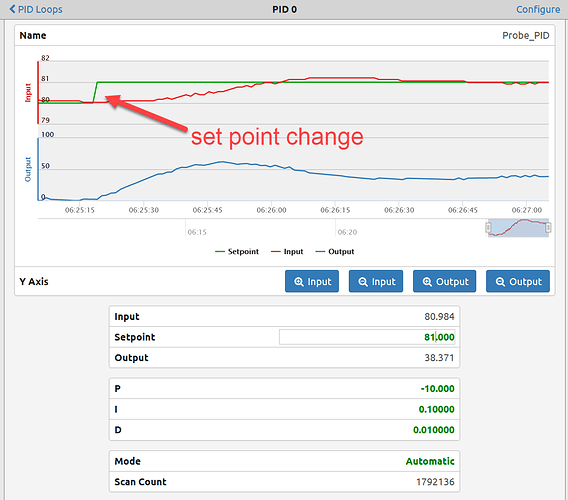

Now for the test:

The PID responds smooth enough for the haphazard tuning values I threw in there to get started.

As expected, there are no jumps in the output when the set point is changed.

Seems to be working out of the box as expected, so lets now test the PID in TPO mode using Node-RED.

To do this, we need to use @torchard flow, you can grab it here (As no doubt you already have since you using the PID loop in TPO mode).

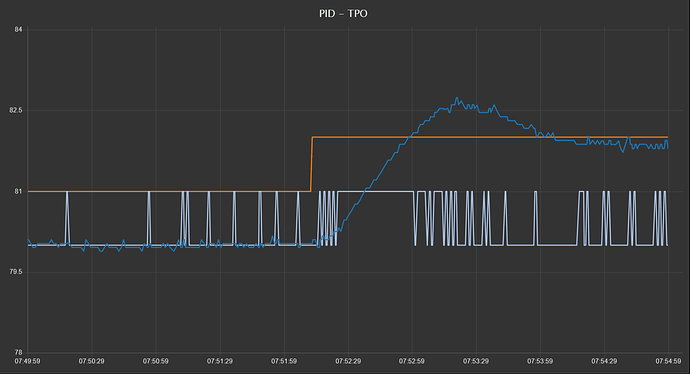

I changed the heater probe from analog to digital and here is the Node-RED graph of a set point change.

The orange plot is the set point. Made a step change in it and you can see the TPO (light blue plot) pick up the duty cycle smoothly, the temperature (blue trace) ie, oven temperature in your case, responds smoothly to the extra energy going to the heater element due to the TPO duty cycle.

The loop is poorly tuned, but none the less, the temp settles at the new set point and the TPO backs off just as it should.

There is no jump, no ‘initial hiccup’, no output spike, just smooth even control as expected.

If there is a PID bug, I cant reproduce it here.

Terry and I would be more than happy to review your Node-RED flow and get the TPO section dialed.

Just let us know how we can help.