Hello all,

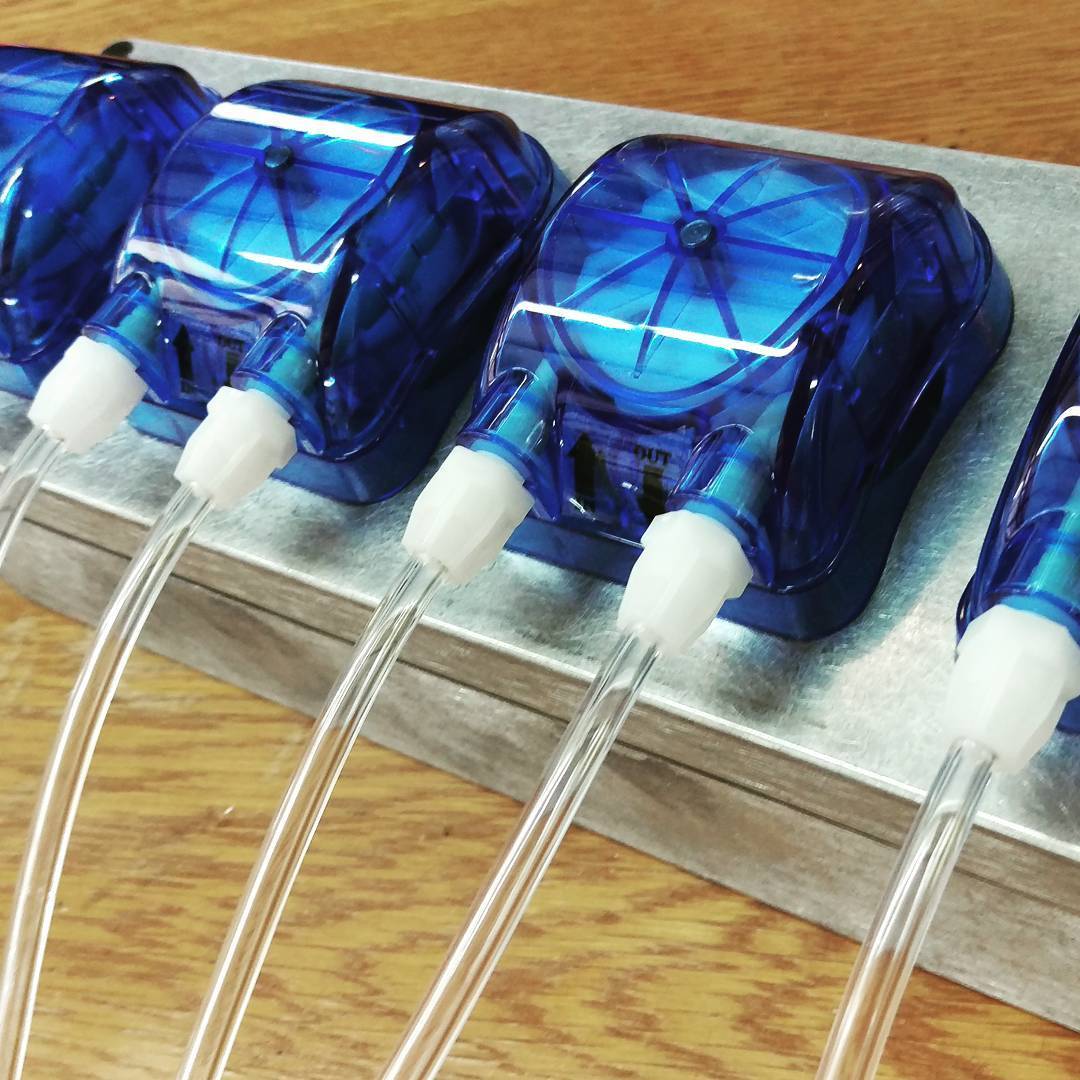

I build a series of products for greenhouse growers…large and small. I have always been more of a software guy, but have bled over into hardware heavily over the last few years. I am trying to build something slightly more modular than a standard panel. With the intro of the RPi kit, I am considering a few products targeting smaller operations. I try to minimize wiring between the modules to make it easier for customers. I am stuck on a clean way to pre-wire plugs between a panel containing the opto relay modules and another enclosure containing 4 small peristaltic pumps (24V). Ideally, I would ship these small enclosures to clients…they mount on the wall…plugin without wiring diagrams…ready to go. Any suggestions for simple wiring between enclosures?

Personally, if I was an end user, I would prefer a cable gland into the enclosure with terminal blocks that I can then bring my own cable into - like thermostat/irrigation cable or the like. Color code the terminals on each end to make the hook-up idiot proof. This would also keep the cost down over specialized connectors and the end-user can decide on the length.

I would prefer the end user not open the enclosure…at all. The units are typically water tight…and the users are not always the brightest…unfortunately. I was thinking about just having an insulated pigtail hanging out via gland of each enclosure with a male/female auto/marine style connector in-between. That would be cheaper…and easy for a user. I have also just considered putting it all in one enclosure, but I lose some ability to customize number of pumps, etc.

Something like a DIN connector? This one isn’t, but they do make water tight versions.

That is what I use now…but what a pain! I like to solder and all…but to spend that much time soldering is a nuisance. If I could find connectors of that type panel mount with pigtail…I would be good. I may be able to special order from Newark, etc…which is something I have yet to pursue.

Not sure what your current requirements are, but if they are low, you could check out waterproof CAT5 cable glands. Never used them, so I’m not sure how durable they are, but they look to be fairly inexpensive.

I just learned about connectors with a “flying lead”…this is the ticket…no more soldering. I will just wire these straight to the relays. Sweet ![]()

https://www.phoenixcontact.com/online/portal/us?uri=pxc-oc-itemdetail:pid=1419690&library=usen&pdfmode=direct&pdflanguage=en

So it looks like I can send 24V through this guy…

http://www.mouser.com/ds/2/324/ItemDetail_1406119-914854.pdf

Any reason to think that wouldn’t be safe? Seems odd that I would be sending that much voltage through an ethernet cable. However, maybe it doesn’t…POE. Curious what you guys think. I am now considering having the 24V PS in the same enclosure with the Opto modules. In theory, I could then power a set of 4 external pumps using the 8 conductor cable above…crazy talk? Each pump pulls up to 160 mA at max load…so plenty of room there.

Edit: They have this hybrid cable specifically for POE…pricey!

Hybrid Cable

Turck makes a lot of these cables as well. Might even be cheaper if you find a good distributor.

It’s just wire - 26 awg with .290 ohms/m resistance according to the spec sheet- do the voltage drop math for your application and see if it’s acceptable (are your pumps okay with 23V when you have 20 meters of cable?). Seems strange being 26 awg when conventional CAT5 is 24 however.

My concern would be with durability as I imagine your end users will likely run this cable exposed.