Hi David,

Okay, I wrote a little code to show how you might log this info to a file, which I’ll also attach (WriteTextFile.Archive.D07182012.T093541.zip (2.59 KB)):

// Initialize info to log to be an empty string;

sInfoToLog = ""; // If it says empty throughout the checks, then we have nothing to log

// Check for trouble

If (IsVariableTrue(Cure_On)) then

if (not(Di_Combustion_North)) then

//save record of di_Combustion_North

// Here's where you log the note to self

sInfoToLog = "Cure_On is true while Di_Combustion_North is not!";

else

//do Nothing and check the next if....

endif

endif

// After we finish checking everything, we'll see if we made any notes

// that should go in the file:

if ( GetStringLength( sInfoToLog ) > 0 ) then // we have something to log

// Build timestamp

DateToStringDDMMYYYY(sDate);

TimeToString(sTime);

// Prepend the date/time and add a CR LF at the end to make it easier to read

sInfoToLog = sDate + " " + sTime + " " +

sInfoToLog + chr(0xD) + chr(0xA);

// assuming chFile has already been initialized to something like: "file:a,LogFile.txt"

// (the "a" after "file:" means we're appending to the file if it already exists

nCHResult = OpenOutgoingCommunication(chFile);

if (nCHResult == 0) then // we opened the file okay

nCHResult = TransmitString(sInfoToLog, chFile);

CloseCommunication(chFile);

else

// we couldn't open the file, maybe log the info to the scratch pad

// or send an SNMP trap instead

endif

endif

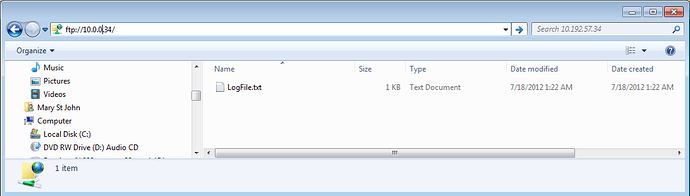

After I run this, a file will be created on my controller. I can see this using Windows Explorer like this:

The contents look something like this (after one time through):

18/07/2012 08:22:37 Cure_On is true while Di_Combustion_North is not!

I’m guessing you’d delete the file after you read it? You would need to make sure you don’t fill up the file space on the PAC – which is about 2MB. Also, if you think the power might go out before you have a chance to read that file, there are options for storing data in non-volatile memory too.

Hope that helps!

-OptoMary