What Beno says here is absolutely true. You can even read the vendors documentation on their modbus implementation and still have it completely wrong once you are talking to the device. The guys that write the manuals are not the same guys creating the implementation. Modbus is the wild wild west of protocols - but you don’t have to pay a multi-thousand dollar license fee for the privilege of getting the specs for it, so there is that.

I’ve worked with some ABB drives using the built-in RS-485 RTU and they were straight forward as far as modbus devices go. I haven’t controlled them over modbus, just read the data I needed - I prefer a field wire if possible for start/stop, speed request, etc - MUCH easier in the field to have someone troubleshoot.

In my experience using modbus to control drives does not usually save money in the long wrong. I recommend buying the modules and running field wire. That way when it comes time to replace the drive and the customer no longer likes ABB, field wire is no problem, it is universal and any drive vendor can re-integrate.

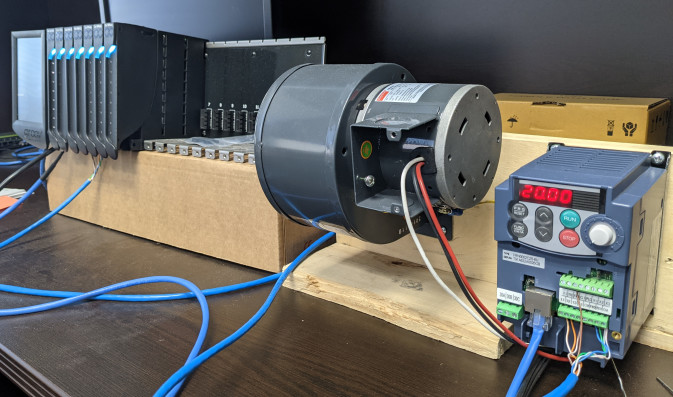

Your best bet here is going to get your hands on the device. Better yet, buy a cheap version that you can setup and have on your bench to experiment with. I have found that drive vendors pretty much use the same register layout from their little drives to their big ones. Here in the US, I like using the 120V ones so I can just setup on my desk: