nvl

Joined on 07-12-2007

Posts 19

Can SNAP PAC system auto detect I/O modules?

Our customers ask the questions regarding I/O modules:

-

Do PAC controller R-series & Brain automatically detect the I/O modules upon they are plugged (hot plug)?

-

Can PAC Manager or PAC control diagnostic the status of I/O Modules?

- to see whether it still works or break few channels. - to see Quality of I/O signals

…

Report

11-08-2007, 5:34 PM

kdowney

Joined on 05-10-2007

Opto 22

Posts 28

Re: Can SNAP PAC system auto detect I/O modules?

-

Brains or rack mounted controllers do not auto detect an I/O module but this is partly because they do not need to. When you create the configuration (either in PAC Control or PAC Manager), you tell the brain or rack mounted controller what module should be there. The brain or rack mounted controller does not really know if the module is there or not. Also, we do not recommend hot swapping modules. Without hot swapping, there is no need for an auto-detection you speak of.

-

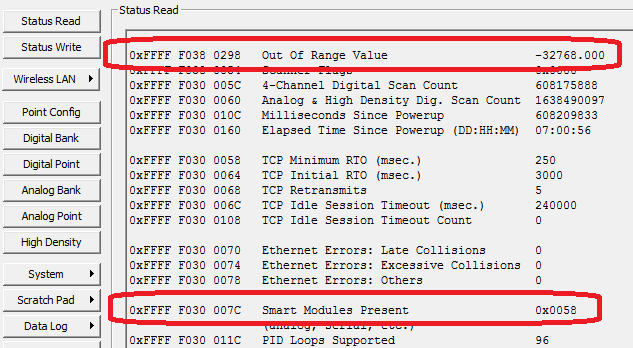

A way you can monitor the state of I/O modules is to create logic in your strategy that will monitor the quality of the I/O. Things you can check for are if the value goes out of range or does not change within an expected time frame.

-Kelly D.

Report

11-12-2007, 7:04 AM

nvl

Joined on 07-12-2007

Posts 19

Re: Can SNAP PAC system auto detect I/O modules?

Dear Kelly,

Thank you. Hope our customers satisfy with these answers.

Report

11-14-2007, 9:58 AM

gmitchell

Joined on 12-01-2003

Optomation Systems, Madrid, Spain

Posts 153

Re: Can SNAP PAC system auto detect I/O modules?

Kelly.

I would actually debate this one. SNAP PAC I/O can be referred to as “The Mother In-Law of all I/O systemsâ€. Let me explain.

SNAP Analog I/O modules and high density actually know full well who they are and where they are on the rack. But they prefer not to say anything while you get on with the work of configuring them on the rack using PACControl or an OTG file.

If you do not make any mistakes then they keep quiet, but if you get one tiny thing wrong, (module type, position etc) then they are more than happy to loudly tell everyone that you don’t really know what you are doing. Finally they convince the PAC Brain not to enable communication with the whole damn SNAP Rack.

Does this situation sound familiar to anyone?

Report

11-15-2007, 8:43 AM

kdowney

Joined on 05-10-2007

Opto 22

Posts 28

Re: Can SNAP PAC system auto detect I/O modules?

George,

You are correct. I should have clarified my answer. When changing identical modules, (taking a bad one out and then replacing it with the same module type) there is no need for auto detecting.

Thanks.

-Kelly

Report

02-19-2008, 6:14 AM

Joshua

Joined on 06-09-2005

Posts 6

Re: Can SNAP PAC system auto detect I/O modules?

gmitchell wrote:

If you do not make any mistakes then they keep quiet, but if you get one tiny thing wrong, (module type, position etc) then they are more than happy to loudly tell everyone that you don’t really know what you are doing. Finally they convince the PAC Brain not to enable communication with the whole damn SNAP Rack.

I could be mistaken, but this is due to memory address issues, ie it’s not that the module says “i’m X at position Y” but that you send something to an address that doesn’t exist when the module isn’t present.

Report

02-19-2008, 2:29 PM

gmitchell

Joined on 12-01-2003

Optomation Systems, Madrid, Spain

Posts 153

Re: Can SNAP PAC system auto detect I/O modules?

Thanks for reading the thread and participating. The OptoForum needs more of this open debate

I understand what you are thinking, but all SNAP modules can be addressed 0-15 on the rack. Each I/O module has its own address. Sixteen modules can be addressed per communications link. Modules are addressed 80 through 8F hex.

4ch digital modules do not need this feature as they require no protocol; they are simply read or written to using 5VDC signals.

Analog modules, special modules and all HighDensity I/O modules are “smart†that identifies its module function. Each module is is actually an addressable analog processor that you can communicate with using either ASCII or binary serial modes.

Pins 1,3,5,7 on the module will connect to define the module address. What’s not so obvious is that the module address is not set on the module, but on the rack when plugging the module into the connector. You can study much more about this by reading the SNAP IO Module Integration Guide.

Analog modules know exactly who they are, you can read this by sending them a command 46 (Identify Module Type) using the SNAP IO Module protocol. That’s part of whats happening when you “configure” the I/O and enable communications on startup. You just don’t see it as it’s hidden within PACControl. But you do see the result if the I/O does not match the configured version, in that the brain will not enable communications because of a module mismatch.

Also the whole possible I/O is completely memory mapped in the brain, (rather like a computer BIOS) whether the modules exist or not. The addresses are predefined. Whether they contain data depends on whether a module has been plugged in. Use PACManager to understand the complete addressing possibilities. You may like to take a look at the Opto 22 hardware memory map section in the MMP Protocol Guide to fully understand the mapping. Its a pretty complex thing!

http://www.opto22.com/site/documents/drilldown.aspx?aid=1875

Hope this information helps. Generally the more you study the PAC and SNAP Product Lines, the more you understand that it’s the most technically “pure†product in the market and has already resolved issues that you haven’t even considered yet! Don’t forget Opto 22 has been continuously developing I/O product lines for the past 30 years, so they do have a slight advantage!