Germinal is an Opto 22 integrator over in Florida.

He wrote the following tech-tip up as a blog entry, but Mary and I felt it was better as a forum topic.

Over to you now Germinal…

Using PAC Controllers and Brains as Gateways (serial to ethernet)

[B]optomizeonline.com[/B]

on August 17th, 2011 at 10:00 PM

Recently we implemented a solution for remote monitoring of Telecom Towers and Facilities. One of the customer’s requirements was to interface with a Power Analyzer via Modbus RTU RS485, so we included an SNAP-SCM-485-422 serial module implementing a simple chart that sends just the modbus command to request from the Analyzer all the parameters at a time (it was pretty simple), then, after receiving the Analyzer’s response we converted all the characters to the values in the engineering units (volts, current, power, harmonics, etc., it was pretty simple too).

The “most nicest” part of the history is that, thinking about how to configure the Analyzer remotely, instead of having to travel to each location with a PC and a RS485 serial port, and instead of having to write a large and boring program (chart, routine, or whatever) to read and write over all the modbus configuration registers, we just installed the original configuration program supplied by the Analyzer manufacturer using the controller as a gateway.

How it was possible? What’s needed?

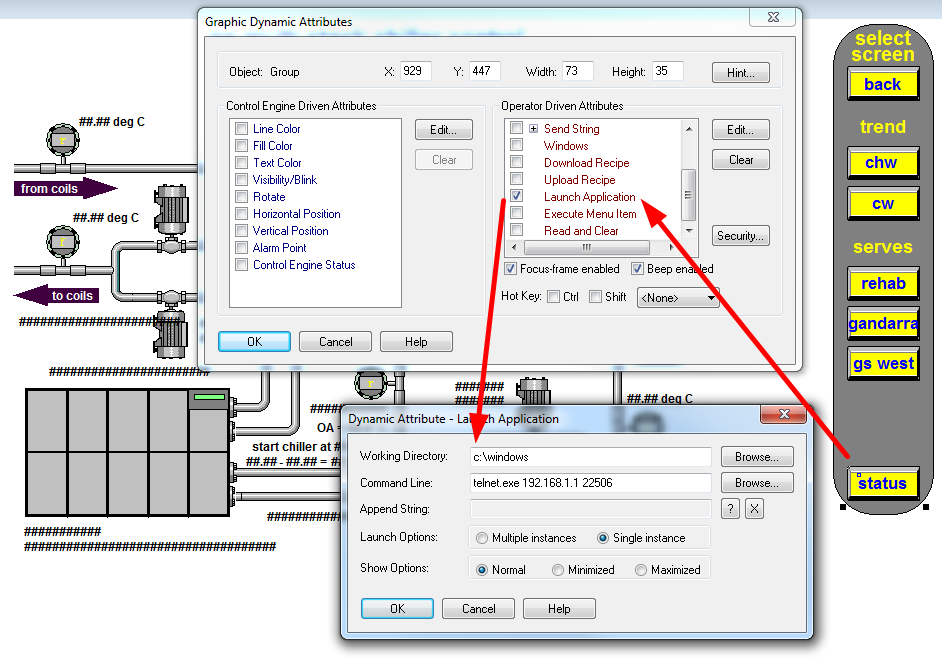

Each serial channel has a TCP port pre-assigned (from 22500 to 22531, can be changed) that can be directly accessed by ethernet using the controller’s IP Address and the serial module’s IP port. So, we used a “Serial to Ethernet Port Redirector” (it’s just a piece of software, there are many on the Internet, some are free) creating a virtual serial COM port in the computer (we named it “COM3”) and redirecting it to the controller’s serial port where the analyzers are connected.

Think about doing the same to monitor or program serial devices like access control readers, UPSs, or to communicate with a router or managed switch connected remotely but directly to its console input without having to stand up from your desktop. I think it’s Cool ![]() , don’t you?

, don’t you?

BRs,

Germinal