We’re using R1 and R2 controllers. And they do have RS-232 built in, but I got a bunch (like 20) of the RS-232 modules when we dismantled six brain/rack setups that an outfit was using purely to do distributed RS-232 interfacing. So I was planning on using one of those modules because with RS-232 being directly wired, rather than having any sort of transformer isolation (the way Ethernet hookups do), I’d get the electrical isolation of the module to protect both the Opto end of things and also help protect the PC end of things in the event of nearby lightning hits and such.

I’ve seen far too many PC motherboards cooked by the differential between ground points during transient events (mostly nearby lighting hits) when people directly connect RS-232 between PCs and/or various gadgets that aren’t, at the least, plugged into the same outlet or outlet strip. This has been especially true where folks connect a PC in an office to a CNC mill or lathe out in their machine shop. Everything is dandy until a thunderstorm, and then poof. Both the PC and the machine’s RS-232 interfaces get popped.

So using the module is just a way of having that electrical isolation (which I’m not sure exists if you use the RS-232 built into the controller). And if I do lose one of these modules, I’ve got 19 more of them laying around that I probably will never need for anything else.

I do have extra NICs on a couple of the PCs I use. I’ve just used external Ethernet interfaces that plug into USB ports, and they’ve worked very well. It’s nice to be able to have both our office network, which is exposed to the internet, and the OPTO systems’ networks available on the same PC. But I still worry that having a PC that is connected to both the internet-connected network and to the OPTO network might provide a route of attack. If the PC gets a virus, why wouldn’t it be able to spread to all of the networks to which the PC is connected? Ever since stuxnet showed what can be done, I’ve had worries.

This location is a municipal water treatment plant (drinking water plant). We try to make things as secure as possible.

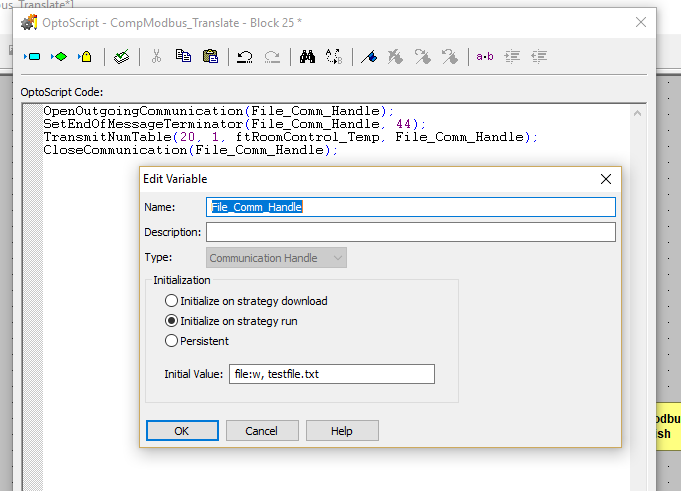

While the RS-232 method is crude, slow, and without a lot of capability, that is actually all I need for this, and seems like it would be completely bomb-proof in terms of someone being able to hack into the OPTO side of things. The beauty, for me, of the RS-232 setup would be that it would be incapable of doing anything except what I explicitly program it to do - in this case, transmit data only, from the OPTO side. It won’t even know or care if the blasts of data are received by the PC side. And I’ve had excellent luck, in the past, with the serial comm tools built into VB. So I feel comfortable with the PC side of a setup like this. I’d just have to do some learning to be able to do serial port comm with the Opto gear.

I might be being too paranoid, but the truth is that when it comes to the ethernet connectivity of all of this, I just don’t know enough about all of it to be certain that I’m not leaving some means of access unguarded. With the serial setup, I’m more confident that there could never be any way for a bad actor to gain access between the internet side of things and even a separate network when both are running on the same PC. It always seems like things we believe to be secure are found to have vulnerabilities that need patching or require us to take additional measures.

Back in the days of DOS, I felt like I actually had a decent grasp on most of what went on behind the scenes in the OS, the hardware, and everything down to the register and bit levels in the PCs. Ever since NT and beyond, I have no confidence at all that I really understand what’s going on behind the scenes. And I get the feeling that there are no individuals who actually understand it all. We just learn the bits and pieces that we need to make things work, and have to take it on faith that everything that supports what we do is solid and secure.

Too much information, and off topic, I guess, but that was just to explain why this serial port business seems somewhat attractive to me.

I do need to learn a lot more about the whole OPTO system and its inner workings. As with most of what I end up doing, I never seem to have the time to delve into any aspect of it deeply enough, so everything I do is based on my weaknesses and lack of knowledge. I make things work, but never feel like I know enough to do things the correct, or even easy ways!

I should take some sort of Opto-22 training. I just hammer away at things and try to get the bits that I need right then to work, and then move on to some other fire that needs to be put out!

So I do appreciate all of the help you folks give me on here. It’s great!